The Science of Hand Comfort & Warmth

Cold Weather Performance Standard EN 511:2006 – What Do Those Numbers Mean?

Frigid conditions offer their own challenges when it comes to worker safety, especially when it comes to those employees who work outside in the elements. Prolonged exposure to freezing temperatures or, harsh winter weather can create serious personal health problems like trench foot, frostbite, hypothermia and, in extreme cases, death.

Frigid conditions offer their own challenges when it comes to worker safety, especially when it comes to those employees who work outside in the elements. Prolonged exposure to freezing temperatures or, harsh winter weather can create serious personal health problems like trench foot, frostbite, hypothermia and, in extreme cases, death.

Protection against the cold is essential and a first line defense to cold weather protection should always start with the hands. The hands are working instruments that start and complete tasks, and no job is successful without them.

For professionals working in extreme temperatures or for those that handle cold objects, winter work gloves are not just an accessory but a vital segment of their safety equipment. Selecting the proper winter work glove that is certified against cold is crucial to personal safety and productivity.

CUT THROUGH THE CONFUSION

Many cold weather work gloves offered in the market meet similar features whether it be the same outer coating, glove liner material, or the glove’s gauge. However, these core features do not effectively showcase the performance of the glove against harsh wintry weather working environments. This is where the EN 511 standard can help cut through the confusion.

The EN 511:2006 cold weather standard specifies the performance requirements for work gloves designed to protect against cold, providing a reliable benchmark for their protective characteristics in cold work scenarios, ranging from outdoor construction sites to cold storage facilities.

EN 511:2006 PURPOSE

The standard evaluates a gloves’ insulation properties, cold resistance, and waterproofness so you can better navigate through the selection process. The purpose of the EN 511 standard is to ensure gloves have the necessary features to provide adequate protection against cold environments. It applies to work gloves that must protect the hands against convective cold down to -50°C and contact cold. Moreover, it assesses the prevention of water penetration, critical in maintaining thermal insulation in frigid conditions.

CLASSIFICATION

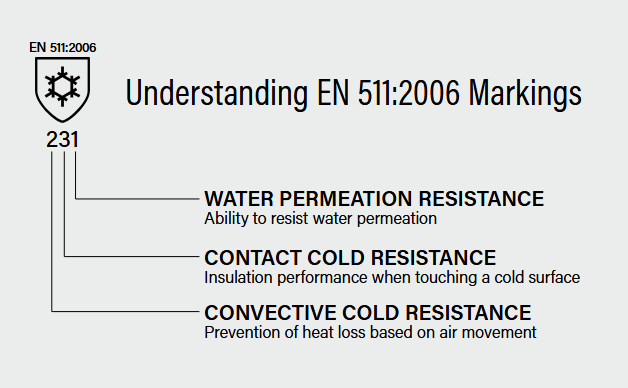

The EN 511 Standard helps users differentiate cold weather gloves by rigorously testing their performance against convective cold, contact cold, contact cold and water permeation resistance but you need to fully understand the EN 511:2006 markings and performance level classifications associated with the glove to ensure it best matches your needs.

If a glove is EN 511 tested it may display a snowflake symbol on the glove. Please note that it is forbidden to show the snowflake symbol on a glove unless the gloves have passed the certification. Under the shield are three digits which symbolizes different properties and protection levels. Because hands can chill down in different ways, there are three different tests and if a glove hasn’t been tested for all the different properties, the glove will be marked with a X.

EN 511 – CONVECTION COLD TEST: FIRST NUMBER

- The first digit (‘A’) represents resistance to convective cold. Convection is the process of losing heat through the movement of air and water such as cold winds and rain. This test measures how much heat a glove can retain when exposed to convection and is rated 0-4 with 4 being the highest value and therefore the warmest.

EN511- CONDUCTIVE COLD TEST: SECOND NUMBER

- The second digit (‘B’) represents resistance to contact cold – the most common test. Conduction is the process of losing heat through physical contact with another object such as frozen construction equipment or materials. This measures the thermal resistance when the glove is in contact with a cold object and is rated 0-4 with 4 being the most resistant and therefore the warmest.

EN511 – WATER PERMEABILITY TEST: THIRD NUMBER

- The third digit (‘C’) represents water penetration or permeability which is the glove’s resistance to water penetration, or in simple terms if the glove is waterproof. This test is important since there are more advanced materials being introduced into the market such as waterproof membranes which keep water out of the glove but allow the hand to breath allowing perspiration to dissipate. A glove is assessed if it can remain waterproof for 30 minutes. Gloves that pass the water permeability test can stay dry inside is rated as one. Gloves that have any water leakage within thirty minutes are rated zero, but a zero rating could still mean that the glove is waterproof but could not stay waterproof when fully submerged in water for thirty minutes.

It is important to note that the EN 511 standard does not explicitly define specific temperatures ranges for each performance level. This is because the wearer’s activity level, duration of exposure and environmental conditions can vary.

DEEP WINTER GLOVE SELECTION

Not all winter gloves are created equally and matching tactility, dexterity, and adequate warmth with the task or function can prove difficult. MDS Associates has winter work gloves to match any wintry weather task. From insulated waterproof mechanic gloves to traditional wool and nylon blends, to Thinsulate™ lined leather drivers and palm coated string knits ... there are glove options to keep your hands dry and warm, without compromising comfort or dexterity. But with all the great choices, how do you know which glove works best for you? While each situation varies and you should consider your specific needs- we are confident we have a winter work glove for you.

+Shop for Winter Work Gloves here

Orders. Questions. Volume Discounts. Special Requests.

Click or Call Today